Technics SL-series Direct Drive Principle Technical explination how it works

Submitted by LeadThis content is © 2005-2025 The DJResource

When you use Technics SL1200's the basic knowledge you'll need to know for everyday life is discussed in the Technics SL1200MK2 topic on the DJ-Resource. This topic goes much deeper into the technical side of the Technics Direct Drive principle. Some things might get a little bit technical but I trust that you have some basic technical knowledge when you're reading this topic.

The Basics

Technics is using the same principle in all of their popular series, this technical story is valid for the following models : Technics SL-1200, Technics SL-1210, Technics SL1200MK2, Technics SL1210MK2.

The Technics SL1200 will be recognized by any DJ from a mile away. But what's inside this beautiful machine? It's as simple as electronics in that days could be. Remember: the Technics SL1200MK2 and SL1210MK2 are nearly unchanged in production since 1982.

Simplified explanation

Most of all the hard work is done by some IC's that control the 3 main sections on the circuit board. There is a Control section (start/stop, 33/45) that receives Pitch information (setting of the fader or calculate Quartz 0%) and uses this to control the Drive section. The Drive IC/section powers the Drive Coils that make your Platter (rotating part of the TT) spin.

Direct Drive

One of the things that makes the Technics SL1200MK2 to an industry standard is it's way of propulsion. Until Technics invented the Direct Drive principle every turntable was driven by a rubber belt. And even today you can still find lots of these deck around, mainly in the lower priced segment. A belt-driven system requires almost no other parts other than the engine itself and the rubber belt. Direct Drive works with another way of power transfer than a belt : a Magnetic Force Field supplies all the power that the Platter needs for it's torque. This power is created using several magnetic fields that are generated in the Drive Coils around the axle of the Platter.

Be aware of Imitations : a lot of manufacturers say that they produce turntables with Direct Drive, using the name that Technics made with it's invention, that works according to another principle. Most of the fakes use an engine that drives the axle directly, the axle of the engine is mounted directly under the center of the axle of the platter. Although this type of 'Direct Drive' has a higher torque than the conventional belt-driven system, it's often far from the performance of the Technics.

Magnets

Magnets

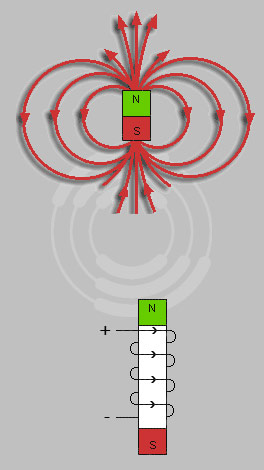

First an introduction into magnetism. Since the whole Direct Drive system is build around this nature phenomenon it's important to understand the basics of it. There are 2 kinds of magnets: permanent and non-permanent ones (electro magnets).

All magnets have 2 poles that attract eachother: North and South. Opposite poles repel eachother. When you should put metal powder on a piece of paper and you put a magnet in the center of it the magnetic field will become visible, just as in this picture. These lines are formed by the curves of the electro magnetic field around the magnet.

Permanent Magnets

The permanent ones are the ones you probably already know, almost every kid once had a magnet (check your fridge). You can find these in almost any size and shape.

Non-Permanent or Electro Magnets

A non-permanent magnet exists out of a metal center piece and a copper wire wrapped around it. When the copper wires is connected to a battery or power supply the metal becomes magnetic as long as the power is connected. When the power is disconnected the magnetism will decline rapidly. Most of it is gone as soon as you switch off the power, the rest will vanish within seconds.

Combine both types

Combine both types

If you combine these two techniques it's the basic and most simple setup. When an electro magnet is connected to DC (Direct Current) the magnetic fields are constant and always at the same place (North and South).

When you put AC (Alternating Current) on the electro magnets the North and South pole of the electro magnet will change according to the current it gets. And since a proper power supply gives you a nice sinus waved current, the magnetism waves smoothly from North to South (or from Positive to Negative, same thing but other name).

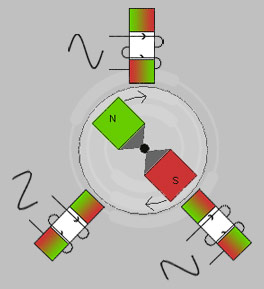

When 3 electro magnets are setup around a Permanent Magnet that is mounted on a very smooth rotating disc, you have the basics of how the SL12xx make that disc rotate. When some electronics are added to control the force on each magnet your system is complete.

How did Technics work this out ?

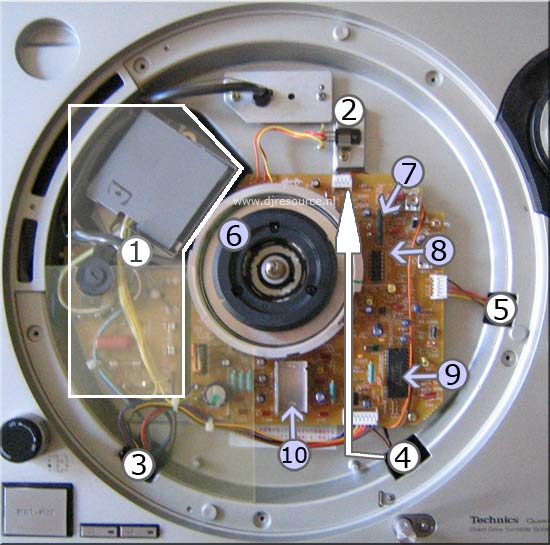

This is obviously only a schematic overview but you can see all essential sections. That's the beauty of the design : Solid and Reliable  When this overview is converted to real-life electronics, it looks like this when you open the cover of your turntable.

When this overview is converted to real-life electronics, it looks like this when you open the cover of your turntable.

- Power Supply

First the power will be converted from 220V (*) to 30V AC. - Power regulation

After that it's regulated down again to a steady 21V DC by this separate Regulator. It's mounted with conductive paste to the chassis so it directs all heat that is created in this process away from the electrics.

The 21V is used for the Stroboscope, Popup Light (official name : Stylus Illuminator), Turntable Drive processor IC101 and the pitch control circuits around IC302.

From this 21V also a 9.4v stream is created to feed the other electronics (mainly the pitch circuits around IC301 and the separate fader panel). - Control Section: Strobe, Pitch, Play/Stop

The leads that leave the mainboard are connected to the Main Controls of the SL1200 and take care of Play and Stop function, the Strobe Light and the Speed Selector function. - Stylus Illuminator

The 2 wires that go into the chassis go to the Popup Light (Stylus Illuminator) and supply it's power. Be careful : the plug that connects these wires to the mainboard is located near the Power Regulator circuits at the back-end of the circuit board.

- Pitch Control

Feeds the setting of the Pitch Fader back to the Drive Control IC and supplies the 0% LED with power. - Direct Drive Coils

Direct Drive gives you more torque at a continuous level in comparison to belt driven systems. In this center unit are the coils that measure the position of the Platter and also the coils that drive the Platter. All calculations are done in the 3 ICs of the SL1200. - Pitch Control IC301

Makes calculations to translate the setting of the Pitch Fader to a certain change in rotation speed of the Platter. - Pitch Lock IC302

Makes the calculations with the Quartz Clock to assure you a steady pitch. - Control IC201

These are actually the brains of your SL1200, from this IC all electronics are controlled and operated. - Turntable Drive IC101

If IC201 equals the brains, IC101 must be the heart of the turntable as it controls the electronic fields that make the Platter rotate.

Via 3 detection coils the IC measures the positions of the Platter, in reaction to this, the 3 drive coils are triggered to create torque on the Platter.

The Technics SL1200 Platter with Permanent magnet

The Technics SL1200 Platter with Permanent magnet

When we take a closer look at the inside center of the Platter you can see two things: A magnetic ring and some small coils around the center (Shown inside the red circle). The small blocks around the shaft of the axle are small coils needed for position detection of the platter.

The outer ring is made out of a highly magnetic alloy. This is the permanent magnet that is powered by the Drive Coils (explained later). A chip is controlling the currents that powers the electro magnets, the more power, the higher the rotation speed.

But all that power would be nothing if the speed wasn't accurate and on a constant level. Technics got that very well under control because the systems detects the position of the platter and can instantly adjust the power when needed to keep the same speed at all times.

Position Detection and Drive Coils

Position Detection and Drive Coils

Around the center of the axle are 3 Position detect Coils (Shown inside the red circle). When the platter rotates these coils detect the position because they pick up the magnetic fields of the coils that are mounted on the axle.

These pulses are used to calculate the power it needs to keep it at the speed that you choose. This may vary when you apply a pitch-bend but will be corrected in an instant.

The power is created by the green block (Drive Coils) that you see around the center. These are round-shaped coils that create a magnetic force field that powers the platter.

What do you think about Technics SL-series Direct Drive Principle ??

Related Downloads

Please consider making this website possible by disabling your Ad Blocker.

Or become a Gold Member, they don't see ads.

There are 8 Comments

in the first paragraph under the headline ?Combine both types? you describe how electric magnets work with direct current but in the text you use alternating current which is wrong.

Maybe you should update that.

cheerio, okman

I have the feeling that the magnet of the monitor is outbalancing the magents of the SL's.

Is it possiible that the magnet of a monitor speaker influences the SL, when the distance between the SL & the monitor is around 5-10cm??

The concequence is that the records are not spinning steady on 33/45rpm but are 'floating'.?Correct?

Soulgrooves, in an extreme situation you could be right, but I've have several times speakers next to the turntables and when you crank up the volume, I never noticed influences on the rotating speed of the platter.

The issue you will get when speakers are close and they get enough power is rumble-feedback or skipping of the needle due to the SPL or vibrations of the desk

Some parts of this website require you to login. Using an account on DJResource has a lot of advantages such as:

Adding Content, getting Notifications, Like content, Downloading and Uploading Images and much more.

Create your account to get involved with the Community

Most visitors online this month : 1.134

Lifetime Pageviews since 2003 : 245.820.871